How to Make a Carousel: Complete Build Guide

Understanding Market Demand For Your Carousel Project

Before starting to build your carousel, it's essential to grasp the market forces driving demand for these dynamic tools. Across various industries, businesses are steadily increasing their investment in carousels to meet operational needs and boost overall efficiency. Automation, for example, is pushing the integration of carousel systems, while the need for space optimization demands innovative vertical and horizontal designs. By looking at real-world examples, we can better understand how to create a carousel that effectively addresses these evolving business requirements.

Why Businesses Invest in Carousels

Businesses are choosing carousels for several compelling reasons:

- Increased Efficiency: Carousels automate material handling and retrieval, saving considerable time and increasing throughput.

- Space Optimization: Vertical carousels, in particular, make the most of vertical space, a crucial advantage in facilities where floor space is at a premium.

- Improved Ergonomics: Carousels reduce manual lifting and reaching, making workplaces safer and more ergonomic for employees.

- Inventory Control: Modern carousel systems often connect with inventory management software for real-time tracking and fewer errors.

This demand for adaptable and efficient solutions is backed by data. The global industrial carousel market was valued at USD 650.8 million in 2022. It's projected to reach USD 969.8 million by 2030, expanding at a CAGR of 5.2%. This growth reflects the need for automation, improved logistics, and manufacturing advancements. Learn more about industrial carousel market trends: Industrial Carousel Market Research

You might also find this interesting: How to Master Your LinkedIn Content Strategy to Boost Business Growth

Carousel Performance: Key Metrics to Consider

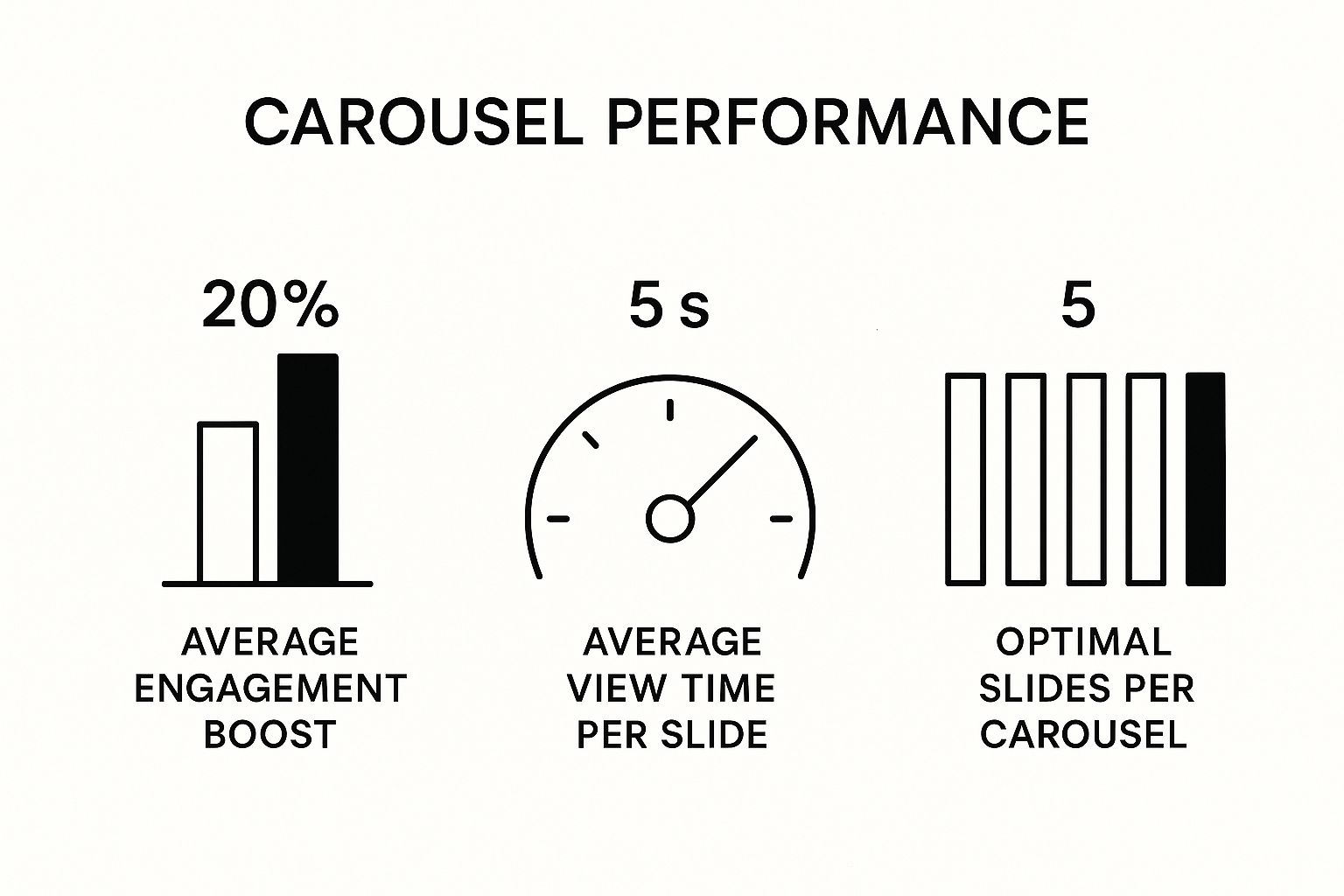

Optimizing your carousel's impact requires close attention to key performance indicators. The following infographic illustrates three essential metrics related to carousel engagement and overall effectiveness.

These insights highlight the importance of both engagement and pacing. A 20% engagement boost shows the potential of a well-designed carousel. The 5-second average view time per slide, combined with the recommended 5 slides per carousel, suggests that concise, visually appealing content is key for capturing and keeping audience attention. When designing your carousel, focus on delivering vital information quickly and effectively.

Applications Across Diverse Industries

Carousels are in increasing demand across many sectors. From manufacturing and warehousing to retail and entertainment, businesses are finding innovative ways to utilize carousels. This widespread adoption demonstrates the versatility and adaptability of this technology. Understanding the specific needs of your target industry will be vital for tailoring your carousel project and ensuring its success.

The following table provides a breakdown of market growth rates and applications across different industries.

Carousel Market Growth by Industry Segment

| Industry | Market Size | Growth Rate | Primary Applications |

|---|---|---|---|

| E-commerce | $150 million | 7% | Order fulfillment, returns processing |

| Retail | $120 million | 5% | Displaying merchandise, improving customer experience |

| Healthcare | $90 million | 6% | Storing and retrieving medical supplies, pharmacy automation |

| Manufacturing | $180 million | 4% | Parts storage, assembly line optimization |

| Warehousing | $210.8 million | 5.5% | Inventory management, order picking |

This table highlights the varied applications and market sizes across different industries. E-commerce and warehousing represent significant portions of the market, driven by the need for efficient order fulfillment and inventory management. Retail, healthcare, and manufacturing also present opportunities for carousel implementation, albeit with differing growth rates and primary applications. Understanding these nuances will help focus your project development.

Strategic Planning That Sets Your Project Up For Success

Smart carousel creation starts with a solid plan. It's about balancing the technical build with practical aspects like budget and space. Just as an architect needs blueprints, a successful carousel project requires careful planning. This ensures a smooth process from initial concept to final construction.

Needs Assessment: Defining the Purpose of Your Carousel

First, understand why you need a carousel. Is it for improving warehouse material handling, showcasing retail products, or something else? A clear purpose guides every decision, from carousel type to materials. A carousel for heavy industrial equipment, for instance, will have different requirements than one displaying lightweight consumer goods.

Carousel Type Selection: Horizontal vs. Vertical

Once you know your needs, choose the right carousel type. Horizontal carousels are generally better for longer, heavier items, offering easy access from all sides. Vertical carousels maximize vertical space, perfect for areas with limited floor space. This choice impacts the carousel's footprint and how it fits into your existing space. For inspiration on a different kind of carousel, check out these examples: Top LinkedIn Carousel Post Examples for 2025

Space Evaluation and Optimization

Space is crucial in carousel design. Carefully measure the designated area, considering the carousel's size and required clearance for access and maintenance. It's like furnishing a room – you need enough space to move around. This prevents costly modifications later.

Budgeting for Success: Avoiding Costly Overruns

A realistic budget is essential. Include materials, components, labor, and potential unforeseen costs. Like budgeting for home renovations, a detailed carousel project budget keeps you financially on track. Market trends are also important. The horizontal carousel market is projected to reach $5,450 million by 2030, with a CAGR of 5.82% between 2024 and 2030. The vertical carousel market is expected to grow at a CAGR of 7.56%, reaching $2.686 billion by 2030 from $1.866 billion. Horizontal Carousel Market Research provides more detailed statistics.

Performance Parameters and Operational Efficiency

Finally, define the carousel's performance expectations. Consider factors like load capacity, speed, and throughput. Establishing these parameters early ensures the carousel meets your operational needs and boosts overall efficiency. Thorough planning creates a solid foundation for a successful carousel project, maximizing its value and lifespan.

Smart Component Selection That Maximizes Performance

Choosing the right components is crucial for a robust and efficient carousel. This involves careful consideration of materials, the motor, bearings, and the control system. These choices directly affect performance, longevity, and cost. It's like building a high-performance engine – every part matters.

Structural Materials: Balancing Strength and Weight

The carousel's frame needs to handle the load while remaining manageable in weight and cost. Steel offers excellent strength and durability, ideal for heavy-duty applications. Different steel grades offer varying properties. Aluminum alloys provide a lighter alternative, useful for smaller carousels or when weight is a primary concern. Your project's specific needs will dictate the best material.

Motor Specifications: Powering the Rotation

The motor is the heart of the carousel. Selecting the right one means considering torque, speed, and power consumption. An underpowered motor may struggle with heavier loads, while an overpowered one increases costs unnecessarily. It's like choosing a car engine – the right power for the task is key.

Bearing Selection: Ensuring Smooth and Reliable Operation

Bearings enable smooth and efficient rotation. Different bearing types offer varying performance and durability. High-quality bearings may have a higher initial cost but can significantly reduce maintenance and extend the carousel's lifespan. This mirrors choosing quality tires for a car – they enhance performance and last longer.

Control System Options: From Basic to Advanced

The control system manages the carousel’s operation, from simple start/stop functions to complex automated sequences. Options range from basic programmable logic controllers (PLCs) to sophisticated software-based systems. The best choice depends on operational complexity and the desired level of automation. It's akin to choosing a computer operating system – it all depends on user needs and technical expertise.

Sourcing and Compatibility: Avoiding Pitfalls

Sourcing components from reputable suppliers ensures quality and reliability. Crucially, ensure compatibility between all chosen components to avoid integration problems. Think of building a computer with mismatched parts – it simply won’t function correctly. Careful component selection is essential for a carousel that runs smoothly, reliably, and efficiently for years to come. This strategic approach ensures optimal performance within budget.

Step-By-Step Construction That Gets Results

Turning your carousel design into a working reality involves a careful, step-by-step construction process. This means approaching each phase with precision, from the initial foundation to the final integration of all the parts. This guide will walk you through those critical stages, offering practical advice for common construction challenges. For additional insights on carousel creation, you can refer to this helpful resource: How to make a carousel post: expert guide

Foundation and Structural Assembly

The foundation is the most crucial element of any successful carousel build. It needs to be level and stable, capable of supporting the carousel's weight and movement. A concrete base might be necessary for larger, heavier carousels. For smaller ones, a reinforced platform could be sufficient. This first step is key to preventing instability and alignment problems down the line.

Next is the structural assembly, where the main frame of the carousel begins to take shape. This phase involves carefully connecting the structural members, ensuring proper alignment and a secure structure. Accurate measurements and strong connections are absolutely vital to the overall integrity of the carousel.

Component Installation and System Integration

Once the frame is assembled, the next step is installing the various components. This includes attaching the motor, bearings, drive mechanisms, and other essential hardware. Correct installation and alignment are essential for smooth and dependable operation. It's at this stage that the carousel begins to resemble its final, functional form.

After the components are installed comes system integration. This connects the electrical system, integrates the controls, and ensures all components work together seamlessly. Think of it as wiring up the carousel’s nervous system, enabling it to operate as one cohesive unit.

Safety Protocols and Quality Control

Throughout the entire construction process, adhering to strict safety protocols is paramount. This means using appropriate safety gear, following established procedures, and proactively taking steps to prevent accidents. Prioritizing safety not only protects the builders but also ensures the final product is safe for everyone who uses it.

Quality control checks are equally crucial at every stage. Regular inspections and testing help identify and resolve any potential issues early on. This proactive approach prevents small problems from becoming major setbacks later, ensuring the carousel's long-term reliability and performance. By implementing a systematic construction process, combined with robust safety and quality control measures, the finished carousel will meet the highest standards. This careful approach sets the stage for a successful and enduring final product.

Regional Adaptation Strategies For Global Success

Successfully launching a carousel system on a global scale requires a deep understanding of the nuances within each target market. Just like adapting a product for different cultures, a carousel system needs to be tailored to specific regional requirements. This includes considering local regulations, existing infrastructure, and even operational preferences unique to that area. Adapting your strategy accordingly can greatly influence your success.

Regional Market Dynamics: Challenges and Opportunities

Every geographical market presents its own set of challenges and opportunities. For instance, regions with well-established industrial infrastructure may require heavily automated, robust carousels capable of handling high volumes. On the other hand, emerging markets might prioritize cost-effective solutions with simpler designs and lower maintenance requirements. Understanding these key distinctions is crucial for effective market penetration.

Additionally, regulatory environments play a crucial role in system design. Different regions have varying safety standards and compliance requirements that must be integrated into the carousel’s design and operation. This careful consideration ensures legal operation and helps avoid potential penalties. The core of any carousel project is construction. For a digital equivalent, see this guide on how to make lyric video.

Furthermore, local operational preferences can significantly influence design specifications. Some regions might favor vertical carousels for space optimization, while others might prefer horizontal carousels for easier accessibility. Recognizing these preferences and tailoring the design accordingly helps meet specific regional needs. Successfully navigating these complexities is key to achieving widespread adoption of your carousel system.

Emerging Markets vs. Established Regions: Tailoring Your Approach

Emerging markets, characterized by rapidly developing economies, present significant growth opportunities. Factors like the expansion of e-commerce and rising labor costs often fuel the demand for efficient solutions like automated carousel systems.

Established regions, with their advanced technological capabilities, frequently drive innovation in advanced features and more complex control systems. This creates a dynamic global marketplace for carousel technology, constantly pushing the boundaries of what’s possible.

The global industrial carousel market is segmented into regions like North America, Europe, Asia Pacific, the Middle East and Africa, and Latin America. The Asia Pacific region is a rapidly expanding market, driven by industrial growth and investment in logistics. E-commerce growth, rising labor costs, and the need for operational efficiency all contribute to this regional expansion. You can find more information on the Global Industrial Carousel Market.

The following table provides a comparison of key market characteristics and requirements across different global regions. It highlights the diverse drivers influencing the adoption of carousel systems, along with the specific technical needs within each area.

Regional Carousel Market Characteristics

| Region | Market Drivers | Technical Requirements | Growth Rate |

|---|---|---|---|

| North America | Automation, high throughput, integration with existing systems | Advanced control systems, robust design, high speed | Moderate |

| Europe | Space optimization, efficiency, regulatory compliance | Modular design, safety features, energy efficiency | Steady |

| Asia Pacific | E-commerce growth, rising labor costs, increasing manufacturing output | Cost-effective solutions, scalable systems, ease of implementation | Rapid |

| Middle East & Africa | Infrastructure development, logistics modernization | Durable construction, adaptability to harsh environments, local support | Moderate |

| Latin America | Growing industrial sector, need for improved supply chain efficiency | Reliable performance, ease of maintenance, local technical expertise | Moderate |

As this table illustrates, adapting your approach to these different market dynamics is crucial. In emerging markets, the focus might be on delivering cost-effective and easy-to-implement solutions. In contrast, established regions might demand state-of-the-art features, seamless integration with existing systems, and high levels of customization.

By understanding and addressing these varied requirements, you can maximize your carousel system's global market impact. This tailored approach will not only increase market penetration but also reinforce your position as a leading provider of innovative carousel solutions.

Advanced Technology Integration For Modern Operations

Modern carousel systems are more than just rotating shelves. They're becoming smart, adaptable solutions thanks to advancements like AI-driven controls, IoT (Internet of Things) connectivity, and automated management systems. These technologies boost efficiency and prepare businesses for the future of material handling. When incorporating new tech into your carousel operations, consider the bigger picture of your video creation workflow for a smooth implementation.

Real-Time Inventory Tracking and Predictive Maintenance

A major advantage of integrating technology is real-time inventory tracking. IoT sensors inside the carousel monitor item location and quantity, providing accurate data for inventory management. This eliminates manual stocktaking and reduces errors.

These sensors also enable predictive maintenance. By tracking factors like vibration, temperature, and usage, the system can anticipate potential problems and proactively schedule maintenance. This minimizes downtime and extends the carousel's lifespan.

Seamless Integration with Warehouse Management Systems

Integrating your carousel with your existing warehouse management system (WMS) further streamlines operations. This connection allows direct communication between the WMS and the carousel, automating tasks like order picking and retrieval.

For instance, when an order is placed, the WMS instructs the carousel to rotate to the correct location, significantly speeding up fulfillment. This automation reduces labor costs and improves overall order accuracy.

Control System Options: Choosing the Right Fit

The right control system is essential for maximizing a carousel's potential. A programmable logic controller (PLC) may be sufficient for basic applications.

However, for complex operations with large inventories and high throughput, advanced algorithms are more effective. These algorithms optimize rotation based on usage patterns. They learn which items are accessed most frequently and position them for faster retrieval. This dynamic optimization significantly improves picking efficiency.

For example, a carousel in a busy e-commerce fulfillment center could use these algorithms to prioritize popular products, reducing order processing time. This responsiveness is crucial in today's fast-paced business environment. Choosing the right control system is like selecting the correct engine for a car – it must meet the specific demands of the application.

Key Takeaways

Building a carousel, whether a physical one for industrial applications or a digital one for engaging online content, requires careful planning and execution. This section highlights the core principles for successful carousel construction, offering practical insights drawn from industry experts and proven methods. These key takeaways will empower you to build efficient, durable, and impactful carousels.

Essential Strategies For Carousel Construction

Successful carousel projects start with a defined purpose and scope. This involves determining the carousel’s intended function, whether it's for material handling, product display, or content engagement. A carousel designed for heavy industrial equipment will have different specifications than one showcasing consumer goods or online content. This understanding guides every decision, from material selection to technology integration. It’s similar to architectural design – the intended use shapes the form and function.

After establishing the purpose, strategic planning is critical. This includes a thorough needs assessment, realistic budgeting, and careful space evaluation. These steps prevent costly mid-project alterations and ensure the final product aligns with operational needs. Defining performance parameters, such as load capacity or content engagement metrics, ensures the carousel meets expectations and delivers value.

Implementing Your Carousel Project

The next phase involves bringing the plan to life. This starts with selecting appropriate materials and components. For example, choosing steel versus aluminum for the carousel structure depends on factors like load-bearing requirements, weight limits, and environmental impact. Similarly, the motor, bearings, and control system should align with the carousel's specific application and performance objectives. Much like a car requires the right engine, a carousel needs properly matched components.

The construction phase demands a methodical, step-by-step approach. This includes careful foundation preparation, precise structural assembly, and meticulous component installation. This detailed process ensures the carousel's durability and reliable performance throughout its lifespan. Think of it like following a recipe – precise execution of each step is essential for a successful outcome.

Ensuring Long-Term Success

Beyond the initial build, regional adaptation and technology integration are key for long-term success. Regional factors like local regulations, available infrastructure, and market preferences necessitate customizing the carousel design for its operational environment. Some regions may prioritize vertical carousels for space efficiency, while others might prefer horizontal ones for easier access. Just as marketing campaigns target specific audiences, successful carousel projects adapt to regional nuances.

Integrating advanced technology, like AI-driven controls and IoT connectivity, enhances the carousel’s functionality. These technologies enable real-time inventory tracking, predictive maintenance, and seamless integration with existing systems. This transforms the carousel into a smart, adaptable solution, optimizing efficiency and preparing businesses for future demands.

By applying these key takeaways, you can approach carousel construction projects with confidence, building systems that not only meet current needs but also adapt to future challenges.

Ready to transform your content into captivating carousels? Lumeo helps you create visually appealing and engaging carousels to maximize your online impact.